PRATT AND WHITNEY AEROSPACE COMPONENT OPTIMIZATION PROJECT (CAPSTONE)

Team Member

(September 2021 - April 2022)

During my fourth year of Mechanical Engineering at the University of Toronto, I had the privilege of working on an incredible capstone project; the optimization of an aerospace component using additive manufacturing for Pratt and Whitney Canada. In this project I was able to develop technical engineering skills including CAD, drafting, machining, and tensile machine operating skills, as well as soft skills like communication and teamwork skills. Not only did I gain an incredible amount of design and testing experience, but I had the privilege of being apart of a dynamic and multidisciplinary team. Furthermore, the supervising professor and P&W client assigned to the team were incredible mentors whose continuous support is what pushed the team to excel.

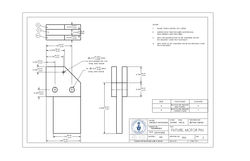

The project consisted of the team designing an aerospace component using additive manufacturing that must withstand a specific load during operation. On my team of five, I took the lead on the physical validation testing design, execution, and results organizer for the proposed optimized component. My tasks included designing custom testing fixtures that acted as adaptors between the component and the tensile machine, due to the unique loading scenario the team was looking to simulate. After these fixtures were 3D modelled using Solidworks and feedback was received from the University of Toronto Machine shop and my supervisor, engineering drawings were produced to get the parts manufactured.

The custom fixtures were manufactured and assembled, where I then conducted preliminary tests on dummy component parts to ensure the test worked as required. Changes to the procedure as well as to the fixtures were discovered and implemented, before moving on to the testing of the final components. A total of 30 final optimized levers were tested, where the force and displacement results for each test were then tabulated into clear and organized graphs using excel. The results were then interpreted and presented to the team, client, and supervisor.

This project has taught me the importance of iteration when designing a new engineering component. Furthermore, additive manufacturing and FDM printing is a field that requires much more testing and analysis before reliable data can be predicted through simulation software. Overall, I was able to design testing fixtures from concept to finished result and was able to create and execute a testing procedure for the optimized components. I am extremely proud of my team and our accomplishments, further highlighted by our supervising professor, who nominated the team for the “Excellence in Multidisciplinary Engineering Design” award.

Special thanks to the team's UofT supervisor, Professor Anthony Sinclair, and the team's P&W client, Barry Barnett, for their incredible mentorship and support throughout and after the project.

|  |  |  |  |  |

|---|---|---|---|---|---|

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|